Vibration control mounts are essential components in various industries for maximizing performance and efficiency. These mounts are designed to mitigate the harmful effects of vibrations on equipment and machinery, thereby ensuring smooth operations and prolonging the lifespan vibration isolators for pipe of the machinery. In this article, we will explore the significance of vibration control mounts in maximizing performance and the various ways in which they can be utilized to achieve optimal results. Whether it's in heavy machinery, automotive applications, or precision instruments, vibration control mounts play a pivotal role in ensuring stability and reliability.

Vibration control mounts are essential for maximizing the performance of sensitive equipment and machinery. These mounts help to minimize the transmission of vibrations from equipment to its surroundings, reducing noise, and preventing damage to both the equipment and its environment. By effectively isolating hanger mount vibration isolator vibrations, these mounts can significantly improve the performance and lifespan of the equipment. Additionally, they can also contribute to a safer and more comfortable working environment for those in the vicinity of the machinery. Overall, vibration control mounts are a critical component in ensuring optimal performance and safety in various industrial and commercial applications.

Vibration control mounts are crucial for optimizing the performance of equipment and machinery. These mounts help minimize the transfer of vibrations, reducing noise and preventing damage to the equipment and its surroundings. By effectively isolating vibrations, these mounts improve equipment performance and longevity. They also contribute to a safer and more comfortable working environment. Overall, vibration control mounts are essential for ensuring optimal performance, safety, and vibration isolation mounts reliability in various industrial and commercial settings.

The Importance of Vibration Control Mounts in Industrial Equipment

Vibration control mounts play a crucial role in industrial equipment by reducing the impact of vibrations on the machinery. These mounts are designed to absorb and dampen vibrations, preventing damage to the equipment and ensuring smooth operation. In addition, they can also minimize noise levels and improve the overall performance and longevity of industrial machinery. By installing vibration control mounts, industries can enhance workplace safety, reduce maintenance costs, and improve productivity. Overall, these mounts are essential for preserving the integrity of industrial equipment and optimizing its performance.

Choosing the Right Vibration Control Mounts for Your Machinery

When selecting vibration control mounts for your machinery, it is important to consider several factors. The weight and size of the machinery, as well as the level of vibration it produces, will dictate the type and size of mounts required. It is also important to consider the environment in which the machinery operates, as this will affect the durability and resistance to corrosion needed in the mounts. Additionally, factors such as the frequency and amplitude of the vibrations must be taken into account in order to select the appropriate mounts for optimal performance and longevity of the machinery. Lastly, consulting with a vibration control expert can help ensure that the right mounts are chosen for your specific machinery and application.

How Vibration Control Mounts Can Improve Equipment Performance

Vibration control mounts can improve the performance of equipment by reducing the levels of vibration and shock that the equipment is subjected to. This can help to minimize wear and tear on the equipment, extend its operational lifespan, and reduce the need for maintenance and repairs. Additionally, vibration control mounts can also help to improve the accuracy and precision of equipment by minimizing the effects of vibration on sensitive components. Overall, these mounts can contribute to higher performance and efficiency of equipment in various industrial and commercial applications.

The Role of Vibration Control Mounts in Noise Reduction

Vibration control mounts are an essential component in noise reduction systems. These mounts are designed to isolate vibration and absorb shock, preventing it from being transmitted to surrounding structures and creating noise. By effectively reducing the transmission of vibration, these mounts play a crucial role in minimizing noise levels in various industrial, commercial, and residential applications. In industrial settings, machinery and equipment often generate substantial levels of vibration and noise during operation. By incorporating vibration control mounts, these systems can significantly reduce the impact of these vibrations on the surrounding environment, leading to a quieter and more comfortable work environment. Similarly, in residential and commercial buildings, vibration control mounts can be used to isolate noise and vibration from HVAC systems, generators, and other mechanical equipment, contributing to a more peaceful and enjoyable indoor environment for occupants. Furthermore, vibration control mounts are also utilized in transportation vehicles such as automobiles, trains, and aircraft to reduce the transmission of engine and road-induced vibrations, thereby improving passenger comfort and minimizing interior noise levels. Overall, the role of vibration control mounts in noise reduction is paramount in various settings, contributing to improved comfort, safety, and overall quality of life.

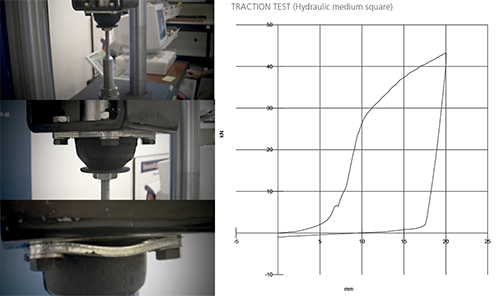

Understanding the Technology Behind Vibration Control Mounts

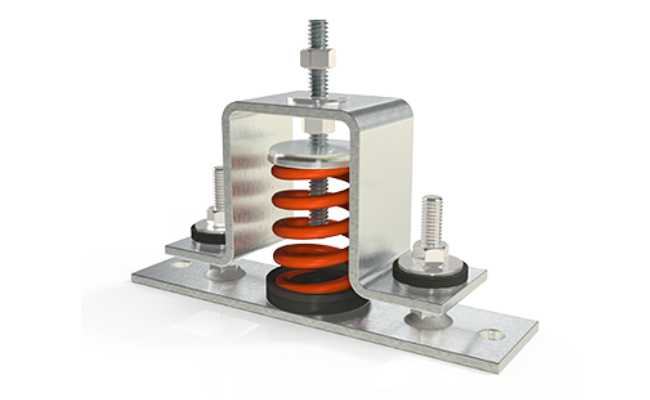

Vibration control mounts are designed to reduce the transmission of vibrations and noises between a source and its surroundings. These mounts are commonly used in industrial and commercial applications to isolate sensitive equipment from unwanted vibrations and ensure smooth operation. They work by absorbing and dissipating the energy of the vibrations, preventing them from transferring to surrounding structures or causing damage to the equipment. The technology behind vibration control mounts involves the use of various materials and design features to achieve effective vibration isolation. Mounts may incorporate elastomeric materials, such as rubber or neoprene, to provide flexibility and damping properties. They may also utilize spring systems or air cushions to further isolate and dampen vibrations. Additionally, the design and configuration of vibration control mounts play a crucial role in their performance. Factors such as load capacity, dynamic characteristics, and environmental considerations are taken into account to ensure the mounts are suitable for specific applications. Overall, understanding the technology behind vibration control mounts is essential for selecting the right solution to effectively mitigate vibrations and maintain the performance and longevity of equipment and structures.

The Benefits of Installing Vibration Control Mounts in Vehicles

Vibration control mounts in vehicles can provide several benefits, including reducing noise and vibration, improving ride comfort, and extending the lifespan of vehicle components. These mounts help to isolate the vehicle's body and interior from the engine and road vibrations, resulting in a quieter and smoother ride for passengers. In addition, vibration control mounts can also protect sensitive electronic components and prevent premature wear and tear on other parts of the vehicle, ultimately saving on maintenance and repair costs in the long run. Overall, installing vibration control mounts in vehicles can enhance the driving experience and promote overall vehicle durability.

The Impact of Vibration Control Mounts on Equipment Maintenance

Vibration control mounts play a crucial role in equipment maintenance by reducing the transmission of vibration to both the equipment and its surroundings. This helps to prolong the life of the equipment, minimize wear and tear, and ultimately reduce maintenance and repair costs. Additionally, vibration control mounts can also improve the reliability and performance of the equipment, leading to increased productivity and efficiency. By effectively managing vibration, these mounts can contribute to overall equipment reliability and longevity, making them an important consideration in maintenance and upkeep strategies.

Exploring Different Types of Vibration Control Mounts for Various Applications

building vibration isolation

Vibration control mounts are used in various applications to isolate equipment and machinery from vibrations in order to prevent damage, reduce noise, and improve performance. There are different types of vibration control mounts available, including: 1. Rubber mounts: These mounts are commonly used for general-purpose vibration control and are available in various sizes and shapes to accommodate different equipment and machinery. 2. Spring mounts: Spring mounts are designed to provide a high level of vibration isolation and are suitable for heavy-duty applications such as large motors, generators, and industrial equipment. 3. Elastomeric mounts: These mounts are made of synthetic rubber or other elastomeric materials and are used for applications that require a high level of flexibility and resilience to withstand dynamic loads and vibrations. 4. Air mounts: Air mounts use compressed air to provide vibration isolation and are commonly used in applications where precise control over vibration is required, such as precision machinery and laboratory equipment. 5. Active vibration control mounts: These mounts use electronic sensors and actuators to actively counteract vibrations in real-time, offering a high level of control and customization for specific application requirements. It's important to consider factors such as load capacity, environmental conditions, and specific vibration frequencies when selecting the appropriate type of vibration control mount for a particular application. Consulting with a vibration control expert or engineer can help determine the most suitable mount for your specific needs.

In conclusion, vibration control mounts play a crucial role in maximizing the performance and efficiency of various equipment and machinery. By effectively reducing the impact of vibrations, these mounts help to minimize wear and tear, improve stability, and enhance overall operational productivity. It is clear that the use of vibration control mounts is essential for ensuring optimal performance in a wide range of applications.

See also

https://www.hutchinsonai.com/vibration-isolation-products